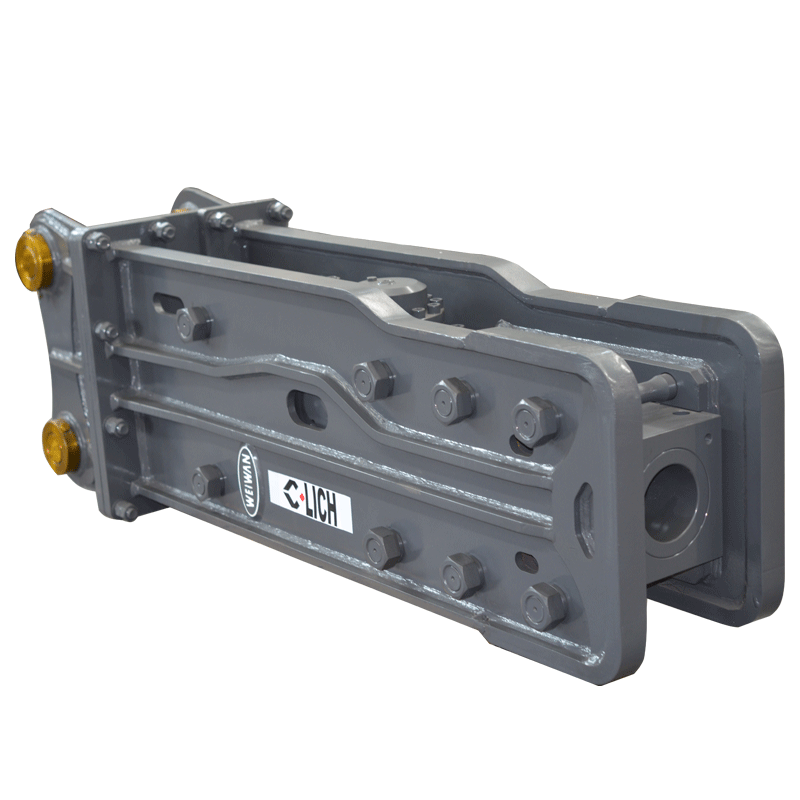

Hydraulic Breaker

Type classification

Classification by weight: can be divided into light, medium, heavy, etc. Breakers of different weight types are suitable for excavators of different tonnages and different working scenarios. Light breakers are generally light in weight and suitable for small excavators. They are often used in urban road repairs, small demolition projects, etc.; medium breakers are suitable for medium-tonnage excavators and can be used for general building demolition, rock crushing and other work; heavy breakers are heavy and require large excavators to carry them. They are mainly used for high-intensity operations such as mining and large rock crushing.

Classification by appearance and structure: Silent breakers use the latest closed shell to protect the main engine design and MIC shock absorption and noise reduction technology, and the appearance lines are smooth; tower breakers are more flexible in demolition and mine risk elimination, and the installation point is relatively high compared to the excavator, and the working range of the horizontal and groove working surface is relatively larger; triangular breakers adopt the best design scheme, made with the least components, with few failures and easy maintenance, and are known for being light, powerful and widely used.

Application fields

Construction and infrastructure fields: used for demolishing old buildings and concrete structures, crushing road surfaces for road renovation, crushing rocks in tunnel excavation, etc.

Mining and metallurgy fields: secondary crushing of ore during mining to facilitate subsequent mineral processing and smelting operations.

Other fields: such as crushing and cleaning of river rocks in water conservancy projects, and crushing of hard materials in some special projects.