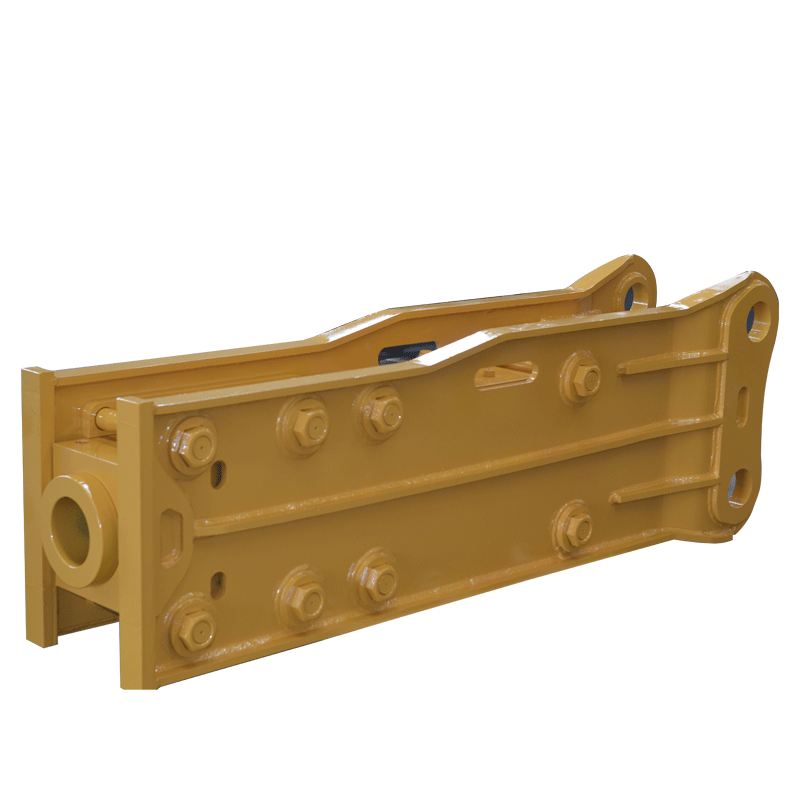

One piece top type hydraulic breaker hammer for excavator

One piece hammer top type hydraulic breaker hammer for excavator

We're here to help: Easy ways to get the answers you need!

Advantages of using one piece breaker hammer

| Item | Model | Weight | Overall length | Hydraulic working pressure | Hydraulic oil flow | Setting Pressure | Impact Rate | striking energy | Hose diameter | Chisel rod diameter | Suitable Excavator |

| Units | (kg) | (mm) | bar | (L/min) | bar | (b.p.m) | (j) | (inch) | (mm) | (ton) | |

| LC-40 | LC10 | 79 | 936 | 90~120 | 15~30 | 130 | 600~1100 | 204 | 1/2 | 40 | 0.5~1.2 |

| LC-45 | LC20 | 105 | 1071 | 90~120 | 20~40 | 140 | 600~1100 | 280 | 1/2 | 45 | 0.8~1.5 |

| LC-53 | LC30 | 166 | 1170 | 90~130 | 20~50 | 150 | 600~1100 | 406 | 1/2 | 53 | 1.5~3.5 |

| LC-60 | 227 | 1280 | 90~130 | 20~50 | 150 | 600~1100 | 722 | 1/2 | 60 | 4.5~6 | |

| LC-68 | LC40 | 289 | 1398 | 900~130 | 40~60 | 160 | 500~990 | 1016 | 1/2 | 68 | 4.5~6 |

| LC-75 | LC43 | 410 | 1677 | 120~150 | 50~90 | 180 | 450~980 | 1835 | 1/2 | 75 | 6~8.5 |

| LC-85 | 580 | 1777 | 130~160 | 60~100 | 190 | 360~690 | 2055 | 3/4 | 85 | 7~11 | |

| LC-100 | LC50 | 841 | 1997 | 150~180 | 80~110 | 200 | 350~700 | 3102 | 3/4 | 100 | 10~15 |

| LC-125 | 1337 | 2230 | 160~180 | 90~120 | 210 | 350~580 | 6190 | 1 | 125 | 14~18 | |

| LC-135 | LC20G | 1671 | 2287 | 160~180 | 100~150 | 210 | 350~500 | 6190 | 1 | 135 | 18~22 |

| LC-140 | LC81 | 1977 | 2307 | 160~220 | 120~180 | 210 | 350~450 | 6485 | 1 | 140 | 20~24 |

| LC-140F | LC81F | 2177 | 2307 | 160~220 | 120~180 | 210 | 350~750 | 6977 | 1 | 140 | 20~27 |

| LC-150 | LC30G | 2448 | 2607 | 170~190 | 130~190 | 230 | 280~400 | 9380 | 1 1/4 | 150 | 24~27 |

| LC-155 | LC121 | 2739 | 2700 | 180~230 | 180~240 | 250 | 200~300 | 10930 | 1 1/4 | 155 | 24~33 |

| LC-155F | LC121F | 2787 | 2700 | 180~230 | 180~240 | 250 | 200-400 | 11977 | 1 1/4 | 155 | 27~33 |

| LC-165 | LC131 | 3217 | 2977 | 200~240 | 190~260 | 260 | 150~300 | 13200 | 1 1/4 | 165 | 33~36 |

| LC-175 | LC151 | 3757 | 3220 | 210~240 | 200~250 | 270 | 120~200 | 15500 | 1 1/4 | 175 | 35~38 |

| LC-175L | LC151L | 4257 | 3350 | 210~240 | 200~250 | 290 | 120~200 | 16507 | 1 1/4 | 175 | 36~42 |

| LC-185 | 4307 | 3327 | 220~260 | 220~280 | 300 | 120~180 | 22380 | 1 1/4 | 185 | 37~50 | |

| LC-190 | 4986 | 3537 | 240~280 | 240~280 | 300 | 110~160 | 24280 | 1 1/4 | 190 | 40~50 | |

| LC-195 | 5400 | 3627 | 260~300 | 250~320 | 320 | 100~140 | 25490 | 1 1/4 | 195 | 45~55 | |

| LC-200 | 6388 | 3837 | 260~300 | 260~340 | 320 | 100~140 | 29700 | 1 1/4 | 200 | 48~60 | |

| LC-205 | 6780 | 3847 | 260~300 | 280~360 | 330 | 100~140 | 32260 | 1 1/4 | 205 | 52~60 | |

| LC-210 | 7017 | 3917 | 260~300 | 280~360 | 330 | 100~140 | 35670 | 1 1/₂ | 210 | 55~65 | |

| LC-220 | 7137 | 4047 | 260~300 | 280~360 | 330 | 100~140 | 37280 | 1 1/₂ | 220 | 60~65 | |

| LC-220L | 7520 | 4177 | 260~300 | 300~430 | 340 | 100~140 | 47000 | 1 1/₂ | 220 | 65~100 | |

| LC-230 | 8909 | 4227 | 260~300 | 330~430 | 340 | 90~130 | 49800 | 1 1/₂ | 220 | 70~100 | |

| LC-240 | 92200 | 4257 | 260~300 | 330~430 | 340 | 90~130 | 59800 | 1 1/₂ | 220 | 70~120 | |

| LC-260 | 10888 | 4877 | 260~300 | 420~550 | 350 | 90~130 | 62000 | 1 1/₂ | 220 | 90~150 | |

The advantages of the cone piece breaker hammer mainly include high efficiency, energy saving, environmental protection, and significant advantages in underwater crushing operations.

Compared with traditional hydraulic piston breaker, conjoined straight hammer breaker, especially high-frequency breaker, has the following significant advantages:

High efficiency and energy saving: The high-frequency breaker has outstanding performance in terms of high efficiency and energy saving during work. It can carry out underwater crushing operations without modification, which is particularly important for specific construction environments.

Environmental protection: The high-frequency breaker reduces the damage to the hydraulic system of the excavator caused by black oil or metal debris during construction. It also avoids the damage caused by the hammer itself to the large and small arms of the excavator, thereby reducing environmental pollution.

Advantages of underwater crushing operations: The high-frequency breaker performs well in underwater crushing operations, especially in sandstone, weathered rock, some limestone, and rock conditions with Custer landform structure. Its performance is significantly better Compared with traditional piston breaker.

BREAKER Applicant

Breaker hammer is widely used in ore crushing, construction materials, metallurgical casting, chemical industry and other fields. It is a very commonly used mining equipment. At the same time, breaker hammers can also be used in civil engineering, concrete demolition and other industries.

In short, the use of breakers in mines has many advantages, which can increase the mineral acquisition rate, save energy and reduce emissions, be environmentally friendly, have low maintenance costs and are easy to use. Therefore, it is widely used in the mining field and related industries.

Please send us your request and we will reply to you within 24 hours.

Reach out to us anytime and we'll happily answer your questions.

Tel

+86-371-86663455A breaker is a powerful percussion hammer fitted to an excavator for demolishing concrete structures or rocks.

Demolition grapple is a light duty hydraulic grapple that can be used to the maximum extent for various sorting and handling jobs. Demolition grapple can also be applied to some lighter demolition tasks, such as the demolition of brick and wood structures.

The Clamp Saw is a cutting-edge tool designed for professionals who demand accuracy, efficiency, and safety.

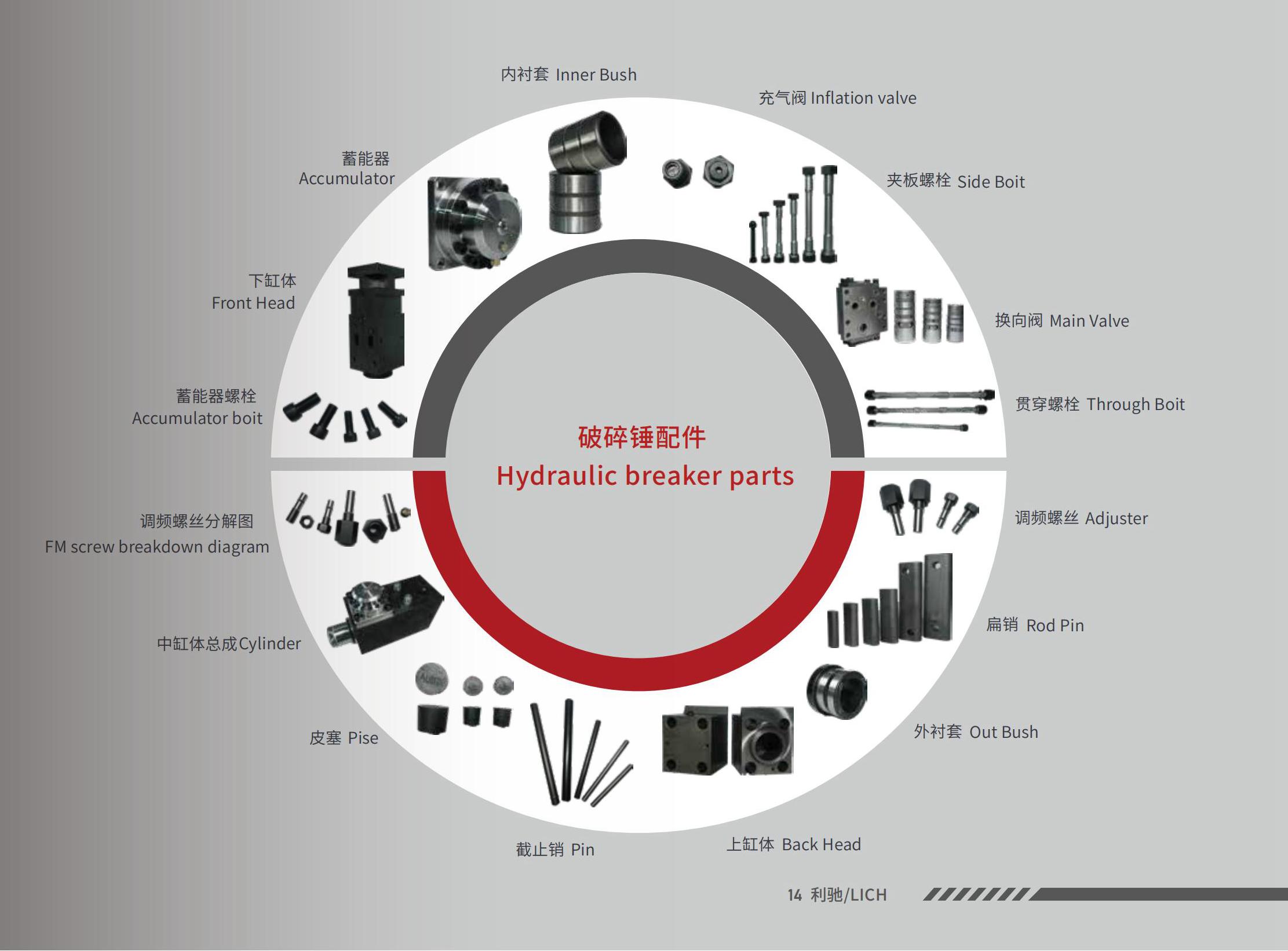

BREAKER SPECIFICATIONS Item Model Weight Overall length Hydraulic working pressure…